Difference between revisions of "Gear Inspection Module"

From ArcoWiki

m (1 revision imported) |

|||

| Line 1: | Line 1: | ||

| + | [[File:Gear_reducer.gif|thumb|right|400px|''https://en.wikipedia.org/wiki/Gear#/media/File:Gear_reducer.gif'']]<br /> | ||

| + | The gear package in Arco allows the measurement of [https://en.wikipedia.org/wiki/Gear Spur and Helical gears] with a CMM.<br /> | ||

| + | The measurement can be performed with: | ||

| + | *Point to Point (trigger) probe | ||

| + | *Continuous Scanning Probe | ||

| + | *[[PH20]] | ||

| + | <br /> | ||

| + | <br /> | ||

| + | By input the nominal data of a gear, Arco produce a program specifics for that gear automatically. <br /> | ||

| + | The preview allows the user to select all the metrologycal parameter for gear inspection such us: | ||

| + | *Limits and number of points for of the Involute | ||

| + | *Limits and number of points for if the Generatrix | ||

| + | *Safety radius for auto probe change | ||

| + | *Identification of the teeth to be measured | ||

| + | *Height of the gear | ||

| + | *Type of alignment within | ||

| + | **Current Reference System | ||

| + | **Plane and Cylinder | ||

| + | **Cylinder | ||

| + | **Synchronization of the tooth only | ||

| + | <gallery widths=400px heights=400px caption="Gear Program Definition"> | ||

| + | File:gearDefinition.png | ||

| + | File:Probe Selection.png | ||

| + | File:Full measuring Preview.png | ||

| + | </gallery> | ||

| + | |||

| + | <br /> | ||

| + | <br /> | ||

| + | |||

| + | |||

| + | Based on the parameter ARCO creates a full program with all the points to be takes and the correct alignment procedure.<br /> | ||

| + | At the end of the execution is generated a PDF report that goes with the international standards, the parameters evaluated are: | ||

| + | *Profile Error (Fa,ffA,fHa) | ||

| + | *Flank Error (Fb,ffb,fHb) | ||

| + | *Quality Class | ||

| + | *Left and Right Pitch Error (fp,Fp) | ||

| + | *Thickness and Run-out (Ues,Aes,Les,Fr) | ||

| + | |||

| + | <gallery widths=400px heights=400px caption="Gear Report"> | ||

| + | File:GearReport1.png | ||

| + | File:GearReport2.png | ||

| + | |||

| + | </gallery> | ||

| + | |||

| + | [[Category:Help_On_Line]] | ||

[[Category:ReadMe3.6]] | [[Category:ReadMe3.6]] | ||

Revision as of 16:05, 17 May 2018

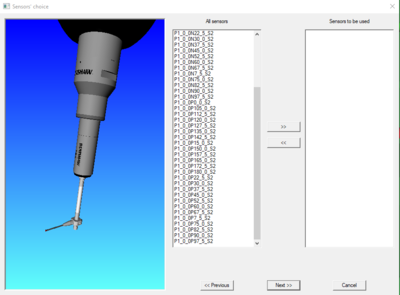

The gear package in Arco allows the measurement of Spur and Helical gears with a CMM.

The measurement can be performed with:

- Point to Point (trigger) probe

- Continuous Scanning Probe

- PH20

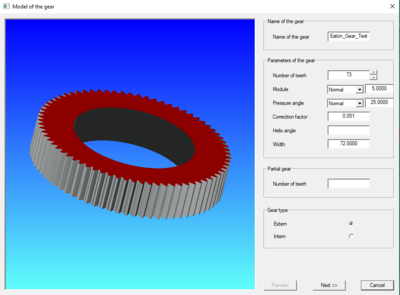

By input the nominal data of a gear, Arco produce a program specifics for that gear automatically.

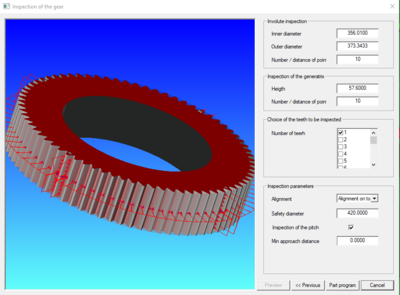

The preview allows the user to select all the metrologycal parameter for gear inspection such us:

- Limits and number of points for of the Involute

- Limits and number of points for if the Generatrix

- Safety radius for auto probe change

- Identification of the teeth to be measured

- Height of the gear

- Type of alignment within

- Current Reference System

- Plane and Cylinder

- Cylinder

- Synchronization of the tooth only

- Gear Program Definition

Based on the parameter ARCO creates a full program with all the points to be takes and the correct alignment procedure.

At the end of the execution is generated a PDF report that goes with the international standards, the parameters evaluated are:

- Profile Error (Fa,ffA,fHa)

- Flank Error (Fb,ffb,fHb)

- Quality Class

- Left and Right Pitch Error (fp,Fp)

- Thickness and Run-out (Ues,Aes,Les,Fr)

- Gear Report